Emissions Reduction

We specialise in reducing emissions and improving energy efficiency by targeting an overlooked aspect of vessel operations - auxiliary systems

Optimising Auxiliary Systems

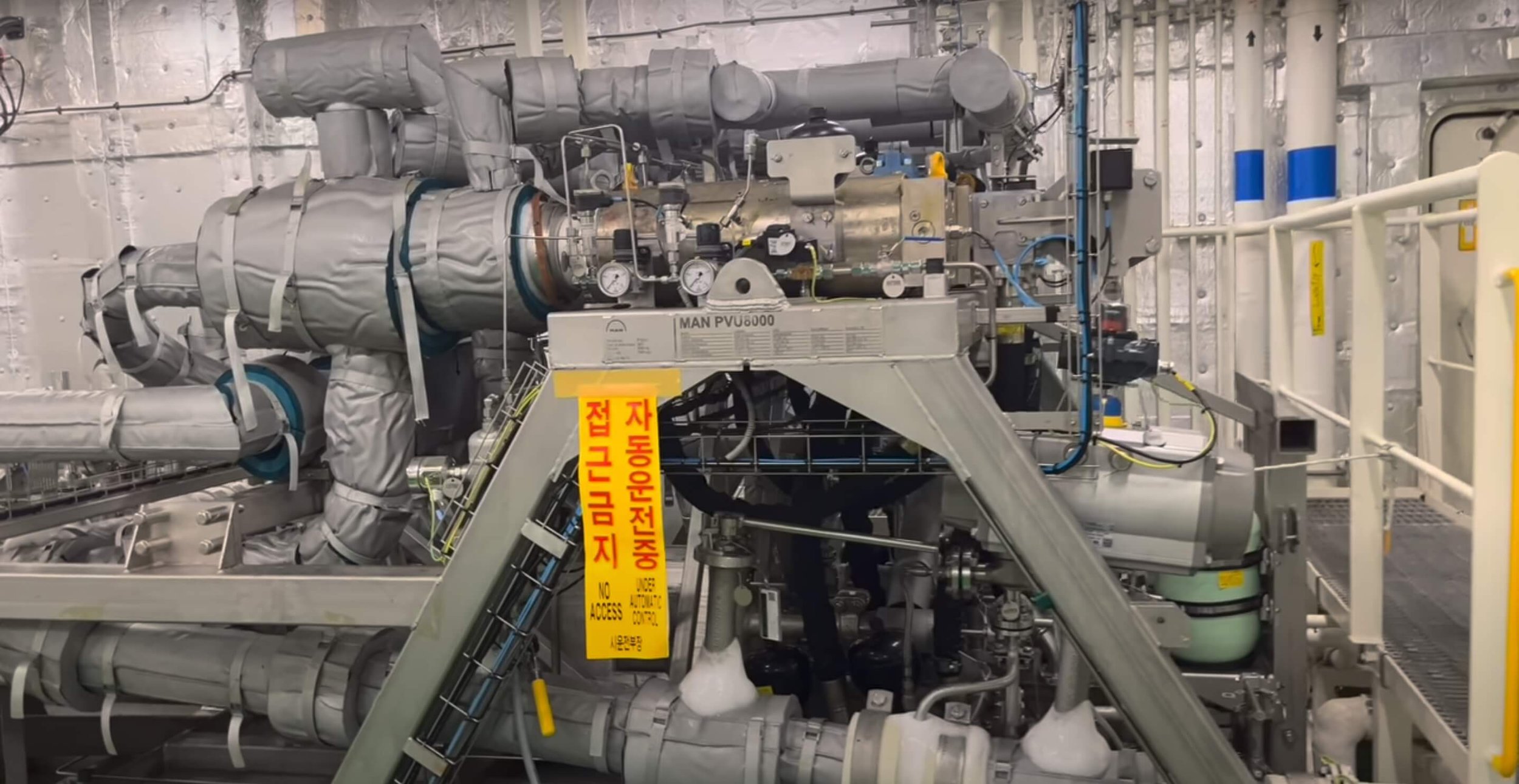

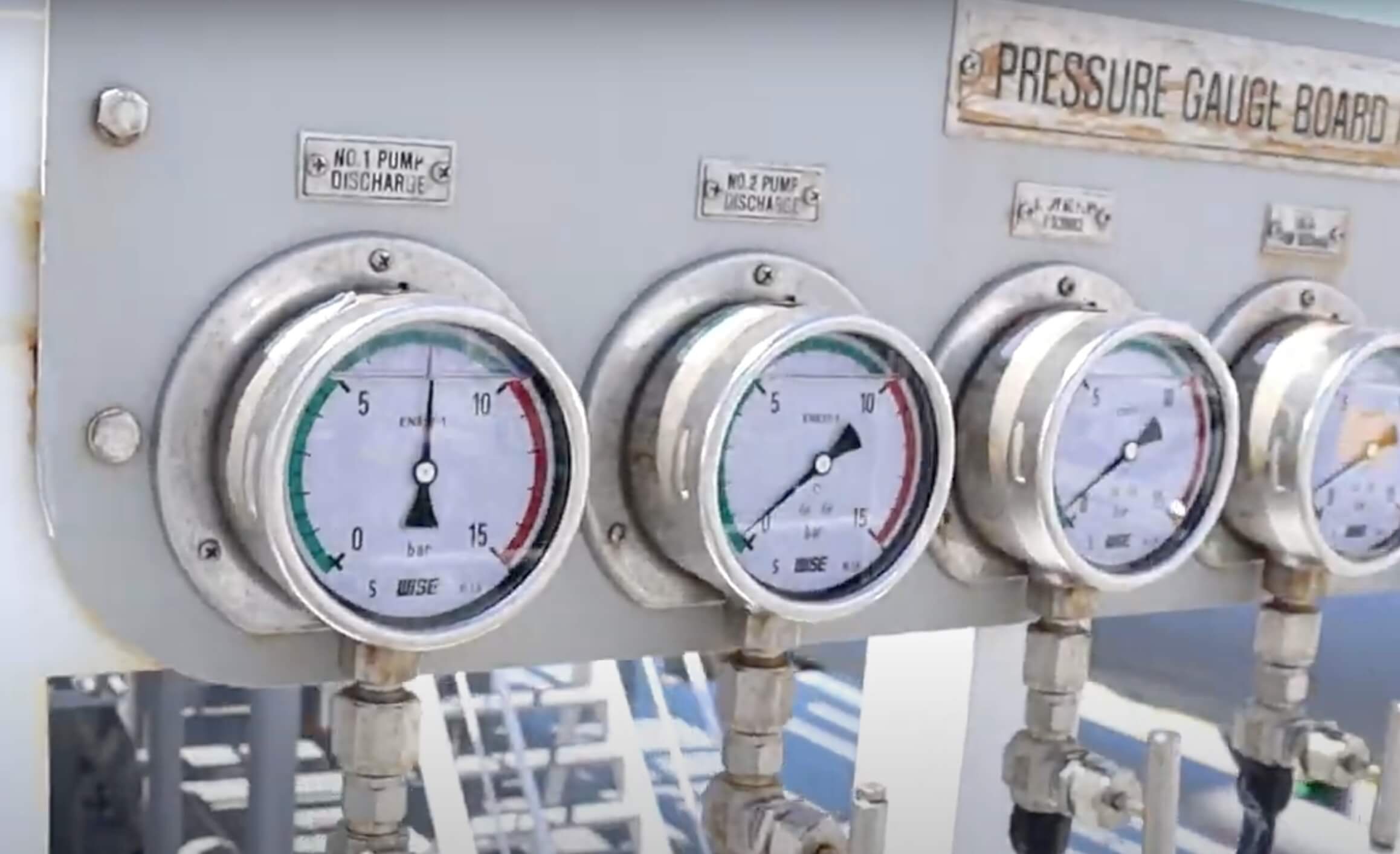

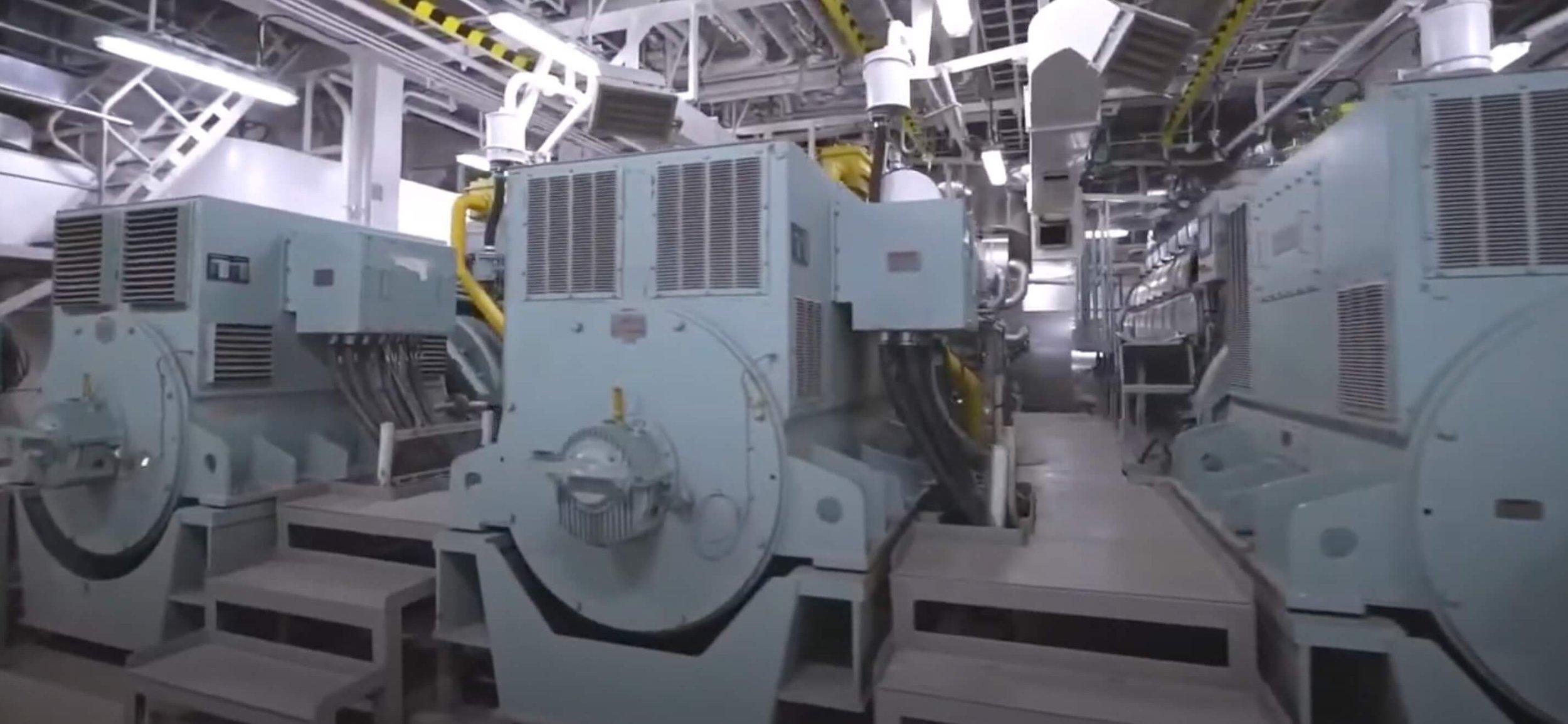

At ER-Marine, we specialize in reducing emissions and improving energy efficiency by targeting a critical yet often-overlooked aspect of vessel operations: auxiliary systems.

These include cooling systems, fuel and lube oil systems, HVAC, steam systems, pumps, fans, heat exchangers, and electric motors—essential components and systems that are often oversized due to conservative design practices. This leads to excessive fuel consumption, higher operational costs, and unnecessary emissions.

Solutions for In-Service Vessels

For vessels already in operation, we identify low-hanging fruit—quick, cost-effective solutions that deliver immediate savings. While some improvements require more effort and investment, we prioritize measures based on the realistic potential for energy savings and return on investment. Our approach ensures shipowners, vessel managers, and charters achieve measurable results with minimal disruption.

Improving Newbuild Ship Designs

For newbuild ships, we provide expert review of technical specifications to ensure auxiliary systems are designed to realistic criteria rather than outdated, oversized standards. By aligning contracts with your operational goals, we help create energy-efficient systems that reduce lifetime costs while maintaining optimal performance.

A Holistic, Cost-Effective Approach

Our holistic analysis takes a comprehensive view of your vessel’s auxiliary systems. We clearly outline penalties and benefits, always including a detailed cost-impact analysis. This empowers you to make informed decisions about where to invest for maximum energy savings and emissions reduction.

The Benefits of Optimised Auxiliary Systems

Reduced Operational Costs

Lower fuel consumption and maintenance expenses.

Regulatory Compliance

Ensure compliance with IMO and EUFuel emissions standards.

Enhanced Competitiveness

Energy-efficient vessels are more attractive to charters and secure better market rates.

Sustainability

Contribute to global emission reduction efforts while improving operational efficiency.